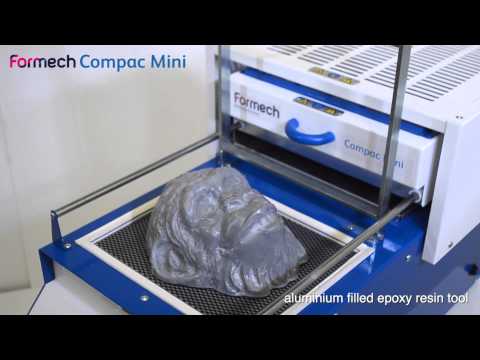

The Companq Mini from Formech is the simplest and smallest vacuum forming machine. This machine is plug & play and with an easy manual operation. The Compac Mini has one heating zone. This Compaq mini is very nicely compact and therefore handy in small spaces. Despite its small size, the Compac mini is made with the most robust materials into a fully-fledged and professional system.

The Compac Mini systems are equipped with an interlocking system that ensures that the table top cannot go up when the heating elements are still hanging above the object to be formed. This makes our desktop machines easy to operate by inexperienced operators. In addition to the interlocking system, the machine also has a timer with beep sound to monitor the correct time settings for the perfect constant cycle. The heating elements are quarz, which means that the machine heats up quickly and is attractive for short runs.

The Compac mini is often used by hobbyists, for users who want to get acquainted with vacuum forming and the process or users who want to quickly and easily mold plastic on a small scale.

The Compac Mini is the smallest desktop machine. In addition to the Compac Mini, we also have two larger systems:

Quartz Heaters

The Quartz heating elements ensure a fast response of the heating and cooling of the elements. This ensures a quick and easy process for piece production and series production. This results in optimal efficiency in the production process and energy savings during use and breaks

Safety Interlock

A mechanical interlock system that ensures that the table top cannot rise during the heating process.This function is available on all desktop models.

Vacuum & Release

After molding, cooled air can be charged between the mold and the formed plastic. This helps the easy release of the plate and the model.

Vacuum Gauge

A visual indication of consistent vacuum pressure in Hg / bar.

Digital Timer

Digital timer with programmable countdown and audible alarm which helps to obtain the consistent production cycle (times).

| Form size (mm/inches) | 230 x 280mm / 9 x 11″ |

| Sheet size (mm/inches) | 250 x 300mm / 10 x 12″ |

| Max. depth | 130mm / 5″ |

| Max. Material thickness | 4mm / 0.15″ |

| Heatingzones | 1 |

| Heatingtype | Quartz |

| Widt | 440mm / 17.3″ |

| Height | 425mm / 16.7″ |

| Depth | 835mm / 32.9″ |

| Weight | 33kg / 73lbs |

| Single Phase energy requirement | 208-240V/13A |

| Europe – 3 Phase energy requirement | N/A |

| USA – 3 Phase energy requirement | N/A |

| Power usage | 1.1Kw |

| External air connection | N/A |

Reducing Windows

Reduce frames that narrow the molding area to use smaller material sheets. This reduces the use of plastic panels.

standard sizes and custom sizes.

Trolley

A specially developed trolley with locking and castors for the desktop machines. Various plate materials can be stored at the bottom of the trolley.

Starter Pack of Plastic

A starter package of sheet material of various plastics (HIPS, ABS, PETG) specially made on the machine you purchase.

Spare parts kit

A package of parts that are easy to replace, such as sealing strips. elements, filter, clauses fuses.